STEEL DETAILING SOFTWARE

Take your PROJECTS

to the next level

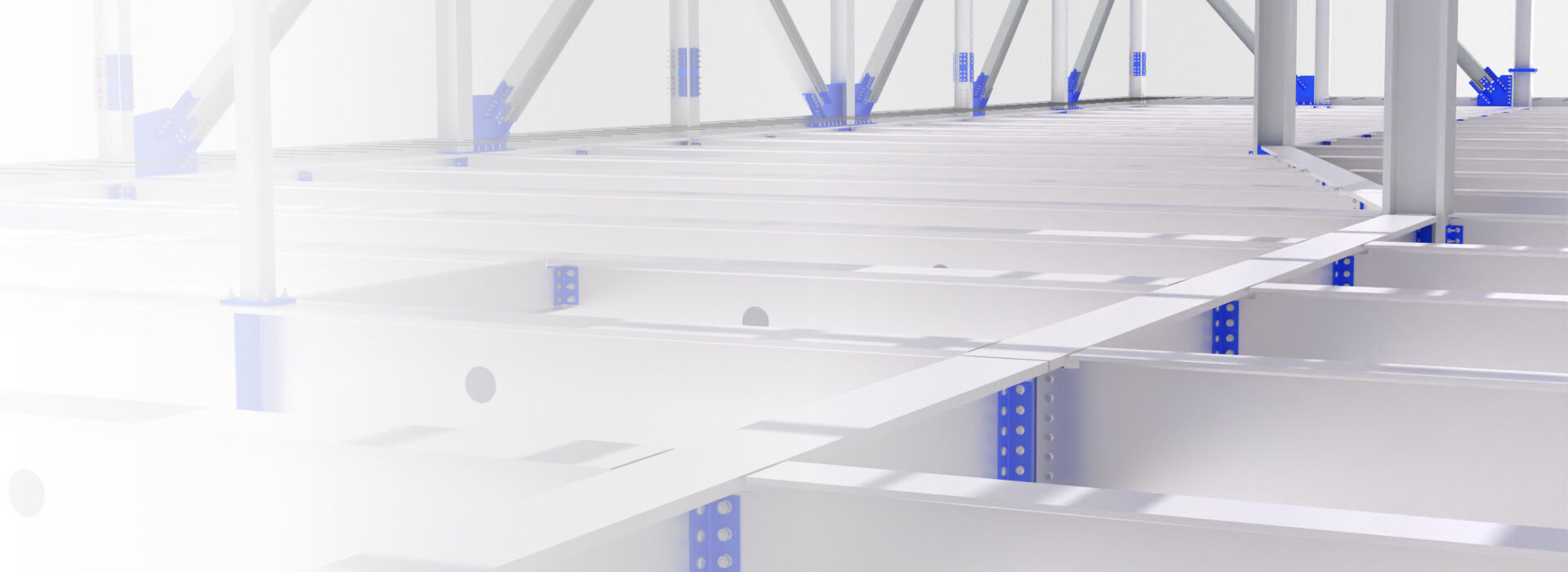

SDS2 DETAILING

Get projects done faster with SDS2’s comprehensive detailing and modeling software, covering all your project needs in structural and miscellaneous steel, stairs and rails, steel connections, and more.

Joslyn Art Museum | Omaha, NE | Project by KL&A

sds2 detailing Features